The defluorination agent developed by our company is a composite product specially designed to solve the problem of fluoride removal in wastewater. It is suitable for the treatment of sewage exceeding the standard in various industries. It has the characteristics of fast reaction speed, high removal efficiency, small amount of addition, easy to add and use, and the removal rate can reach more than 97%.

Product description

The defluorination agent developed by our company is a composite product specially designed to solve the problem of fluoride removal in wastewater. It is suitable for the treatment of sewage exceeding the standard in various industries. It has the characteristics of fast reaction speed, high removal efficiency, small amount of addition, easy to add and use, and the removal rate can reach more than 97%.

Product use

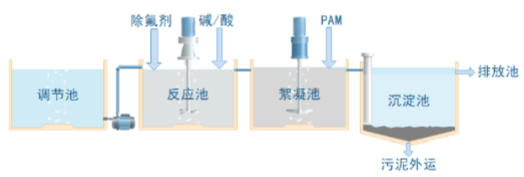

Defluorination agent products can be widely used in various industries to remove fluorine containing wastewater. Defluorination process is simple, can be directly added to the physicochemical treatment of coagulation section or sedimentation tank to add coagulant aid pool. Wide applicability, can be used in pH 2-12 conditions, the best fluoride removal pH 6-7. With high treatment rate and deep defluorination, the total fluorine in wastewater can be reduced to less than 1mg/L.

Product parameters

| Project | Target | |

| Model | JLFL | JLFS |

| State | Liquid | Solid |

| Appearance | Light yellow/colorless | Yellow |

| Effective substance content | >50% | >99% |

| PH | 2-3 (10g/L aqueous solution) | 1-2.5 (10g/L aqueous solution) |

| Density | 1.15-1.3 | |

Packaging and storage

1. A full series of fluoride removal agents can treat all kinds of organic fluorine, inorganic fluorine, high-difficulty fluorine-containing wastewater and high, medium and low concentration fluorine-containing wastewater, and can treat the fluoride content of sewage to less than 1mg/L.

2. Fast sedimentation rate, fast adsorption efficiency and high removal rate. Under the same conditions, the efficiency of fluoride removal is 2-4 times of activated alumina and 8-10 times of zeolite molecular sieve, which can greatly reduce the treatment cost.

3. The whole process without complex equipment and harsh reaction conditions, easy to operate, easy to control.

4. High purity, less impurity content, compared with other products on the market, less dosage, low sludge.